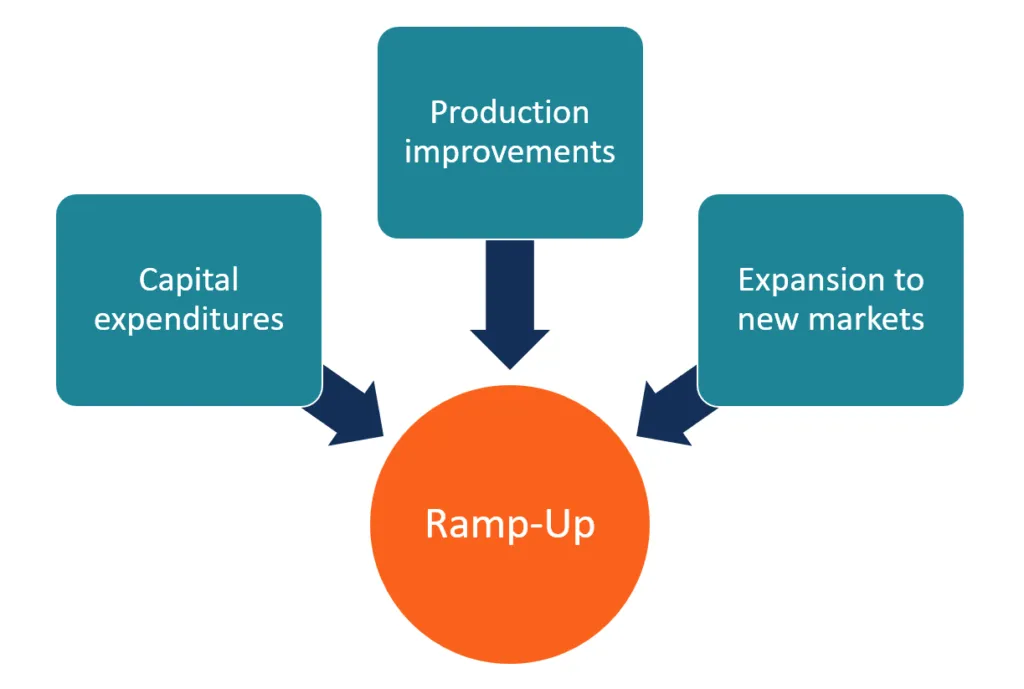

We provide end-to-end support for new product launches by aligning manufacturing schedules with customer milestones, optimizing processes, and managing equipment design and setup. Our expertise ensures quality compliance, timely material availability, and smooth production ramp-up. Beyond launches, we drive cost improvements through process optimization, line balancing, time studies, standard work, and automation—boosting productivity, reducing waste, and lowering operational costs. To enhance customer satisfaction, we apply APQP, PFMEA, and gap assessments, while ensuring ISO/TS-16949 compliance and leveraging benchmarking to deliver robust, reliable results.